The water around your boat is teeming with microscopic life, or fouling, that can attach to and build up on your hull, eventually attracting larger marine life such as mussels and barnacles. Over time this reduces the performance of your boat and increases fuel consumption and fuel costs, but this build up of marine growth can be minimised with the use of antifouling products.

There are lots of different types available for boat owners to choose from; from the more traditional but less environmentally friendly copper-based antifouling paint (also known as bottom paint) to new technologies such as our electronic antifouling systems. This blog will talk you through all the options to help you decide which is best for you and for the environment.

Types of traditional antifouling paints

There are several types of antifouling paint coating to choose from.

Hard antifouling paint

This type of antifouling paint is best for fast or racing boats, boats moored in fresh water or boats which never go above 10 knots. It is also suggested to use hard paint on high-traffic areas such as propellers and for boats which will undergo underwater cleaning. Hard paints works by slowly releasing biocide from their surface (a process known as contact leaching) to prevent marine organisms from attaching.

As with all antifouling paint, hard bottom paint requires annual renewal. However, this type of paint will wet sanding after a few seasons in order to remove the build up before new paint can be applied.

There are several downsides to hard antifoul paints though; the sanding of old paint films on the hull surface produces lots of toxic waste that can be inhaled or potentially damage the environment and the process of contact leeching can release biocide steadily into the water, impacting sea life.

Soft or ablative paints and self polishing paints

Soft or ablative bottom paints are worn away as the boat hull moves through the water, leaving a layer of fresh biocide on the surface. These were designed to be more economic for commercial vessels but work well on most boats that are used regularly and travel above 10 knots.

The erosion of the biocide-containing film to prevent marine fouling as the boat moves does mean that these soft or ablative bottom paints are particularly bad for the surrounding wildlife, particularly in a local marina. Furthermore a new coat is required on annually to replace the biocide-containing layers that have been eroded.

A small subset of soft anti fouling paint is know as self polishing, so called because it gets smoother over time. Self polishing paints have a more complex chemical make up which allows the paint film to erode and release biocide at a much more precise and consistent amount, making them favourable for use on larger boats or boats where longer periods between maintenance is desirable.

Bottom paint active ingredients

Antifouling paints can vary based on their main biocide or pesticide ingredient. The most potent biocide tributyltin (TBT) was largely banned for use by bottom paint manufacturers in 1987 due to its ability to cause sex changes in whelks and deformities is oysters.

Since the ban on TBT, the majority of paints now contain copper as their biocide, some with additional “booster biocides” added to improve efficacy. The most common form of copper used in antifouling is copper oxide (or cuprous oxide) which is safer but has a strong colour copper thiocyanate can be used on aluminium boats without causing galvanic corrosion but is, however, more toxic than copper oxide. Other alternatives such as zinc pyrithione are not only toxic themselves but, once hydrolysed, produce more stable compounds that are toxic to a wide range of marine organisms including bivalves and crustaceans.

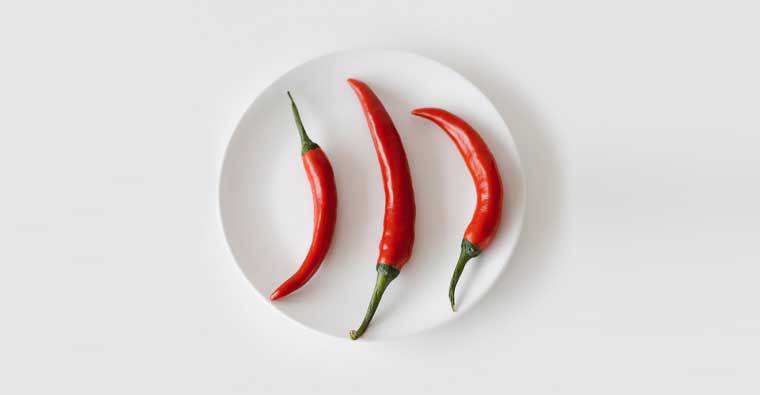

Interestingly, as a more environmentally friendly alternative capsaicin, the chemical that makes chilli peppers hot, is now being used in some antifouling products, encased within a polymer-based composite coating. Studies have shown good results in preventing marine growth particularly the formation of the algae biofilm, as well as having antibacterial properties.

Interestingly, as a more environmentally friendly alternative capsaicin, the chemical that makes chilli peppers hot, is now being used in some antifouling products, encased within a polymer-based composite coating. Studies have shown good results in preventing marine growth particularly the formation of the algae biofilm, as well as having antibacterial properties.

Ultrasonic antifouling solutions

Electronic ultrasonic antifouling solutions are becoming more and more popular as an antifouling alternative as people realise their low environmental impact and ease of application and use. These systems work by using transducers attached to the boat hull which produce sound waves at an ultrasonic frequency. These waves cause the hull to vibrate and create microcurrents which prevent marine growth from attaching. Furthermore, it can even help reduce 4-5mm of pre-existing fouling.

Electronic antifouling is the best antifouling to use if you want to reduce your impact on the environment – they have no negative impact on marine life besides helping to prevent marine growth on your hull and significantly reduce the frequency of having to apply new antifouling paint layers from annually to every three to five years!

Ultrasonic antifouling not only protects from hull fouling but also can be used on sea chests and pipes too to prevent them from becoming fouled and affecting water flow. Our special ultrasonic antifouling units have the option of solar power too, you can read about all of the different products here.

Although ultrasonic antifouling is suitable for most boat types you may want to check out our previous blog to make sure ultrasonic antifouling is suitable for your hull type. Aside from this is is one of the most effective ways of antifouling your boat, with a reduction is biofouling of 80% being widely reported.

Less common antifouling types

Electrolytic antifouling

This technique uses copper and aluminium or iron anodes to prevent biofouling in the sea chest and piping of larger vessels, as well as giving protection to valves, ancillary equipment, condensers and engine cooling equipment.

Passing an electric current through the anodes releases copper ions into the sea water which works in a similar way as traditional biocide paint to kill marine organisms and prevent them from settling or attaching. As with paint coatings, this method also releases toxic copper into the surrounding water which can negatively impact the marine ecosystem.

Chemical dosing of sea chests

Iron chloride (also known as ferrous chloride) can be added to sea chests to prevent biofouling build up in the piping network. The ferrous chloride also helps prevent corrosion in the pipework by forming a coating on the surface.

As with any form of chemical antifouling there is an environmental toxicity risk to using the chemical dosing method.

Electro-chlorination

Chlorine is produced by electrolysis, along with other elements, to produce sodium hyperchlorite (known in a dilute solution as bleach) which is the chemical that prevents the biofouling.

Not only is sodium hyperchlorite potentially damaging to the environment, the process wears away the anode over time and will have to be regularly replaced.

The best option…

The form of antifouling you opt for will depend hugely on the vessel you have; the material of the hull, the length and your budget.

For a cost effective alternative that saves not only your time on annual maintenance but also benefits the environment, we strongly recommend our ultrasonic antifouling systems. They are highly effective against biofouling without damaging the surrounding marine life of using toxic chemicals that build up in the food chain. You can view prices and order directly from our website.