No matter what your boat type you will need some kind of antifouling in place. This blog will talk you through your options depending on your boat hull material, access to the hull and boat size.

Why is antifouling important?

Do you need to antifoul your boat? The short answer is yes! The build up of algae and single cell organisms on your boat hull attracts other marine life such as barnacles and mussels which are further up the food chain and feed on the algae, attaching themselves in the process. This build up of marine life, particularly along the waterline length, leads to increased resistance in the water which, in turn, leads to increased fuel consumption, increased fuel costs, decreased performance of your boat. Marine foul can even cause damage to the boat hull if left to accumulate for too long.

How do traditional antifouling methods work?

Antifouling prevents the attachment of algae and other marine fouling, therefore preventing further growth from attaching which feeds on the algae. Thus reducing fuel consumption and increasing performance of your boat, allowing you to maintain speed and get more out of your vessel.

Traditional antifouling methods are paints (also known as “bottom paints”) which are applied as gel coats to the hull and other high traffic areas such as steering gear. Multiple antifouling coatings are required to maintain the boat throughout the season before the boat needs to be lifted out and the antifouling redone.

Not only is the paint used extremely toxic to marine life – it is a type of pesticide after all, the yearly (or even more regular) dance of lifting the boat out of the water in order to clean the hull, remove the existing paint and reapply the antifouling paint to the boat’s clean hull is the worst job of many a boat owner. This is where ultrasonic antifouling systems come in, a more modern antifouling solution for your boat’s needs that reduces the use of harmful, copper-containing bottom paints.

How does ultrasonic antifouling work?

Ultrasonic antifouling kits use transducers, controlled from a central control unit, attached to the boat hull. These transducers emit multiple bursts of super high frequency waves, these are known as ultrasonic as they are beyond what us humans can hear.

Prevent marine fouling

The very high frequency waves travel through rigid surfaces like most boat hulls and create microscopic bubbles with micro jet action. These form pockets of positive and negative pressure and microcurrents around the hull of the boat, preventing algae and other marine growth from attaching.

Different frequencies of sound wave determine the effectiveness of the ultrasonic systems with certain frequencies more effective than others at preventing fouling. At EFC, our transducers produce ultrasonic waves at a frequency of 20-40kHz, the best frequency for preventing hard fouling such as barnacles, tube worms and molluscs from attaching. These ultrasonic frequencies have been shown not to affect marine mammals that communicate by ultrasonic (sonar) navigation such as whales and dolphins.

Saves time and money

Ultrasonic transducer technology reduces the need for annual antifouling. Instead, boats using ultrasonic systems can leave their boats up to five years before having to reapply the antifouling paint, making it a very time-saving technology as well as reducing repainting costs, making it cost effective too. You can read more about how often you should antifoul your boat in our blog post here.

Does ultrasonic antifouling work on all boat types?

Just as traditional copper-based antifouling paints cannot be used on aluminium hulled boats, similarly, there are some limitations to the use of ultrasonic antifouling systems too. So before you invest in a state of the art ultrasonic antifouling system, read through to check your boat meets our guidelines below.

Boat size

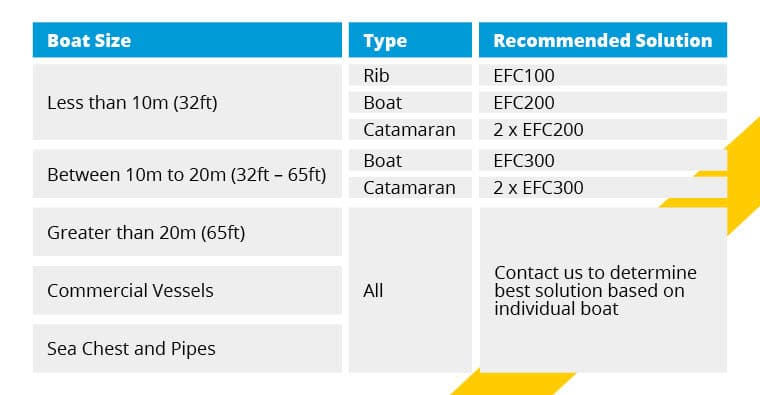

It is really important that, to get the most out of your ultrasonic antifouling kit, you select the correct system to begin with that contains the correct number of ultrasonic transducers for your hull size.

Our size guide below should help you to decide which ultrasonic antifouling system you will need for your boat. For Ribs the EFC100 will do the trick, for boats less than 10m we suggest using the EFC200 and boats between 10 and 20m the EFC300 is best. Remember that for catamarans you will need two of whichever system – one for each hull.

Ultrasonic antifouling can also be used on sea chests and pipes but we recommend speaking to one of our team to check you have the correct product for your needs.

Access to the hull

In order to fit the ultrasonic transducers properly, access to the inner surface of the outer skin of the hull is essential. If this part of the hull cannot be accessed, for example due to a filled cavity, then ultrasonic antifouling will unfortunately not be effective on your boat.

Hull material

Sound waves travel best and fastest through rigid, solid materials. There are several limitations to the use of ultrasonic antifouling technology when it comes to what material the hull of your boat is made from. Ultrasonic antifouling works best on steel or solid FRP/GRP (fibre or glass-reinforced polymer) hulls.

Firstly, ultrasonic antifouling systems cannot be used on boats with wooden hulls. Wooden boat hulls have too low a density and therefore poor acoustic transmission. This means they are unable to effectively transmit the ultrasonic waves in order to prevent marine fouling, therefore our products should not be used on wood.

Secondly, ultrasonic antifouling systems are not effective on cored hulls. These boat hulls have a cored foam material in between layers of fibreglass, something which has been used to create a more lightweight and stiff boat. However, the low density of the foam and the air gaps within it dampens the ultrasonic waves and prevents them from being transmitted effectively.

Proper installation and transducer positioning is key to success

Ensuring the transducers are correctly installed and positioned is key to effective ultrasonic antifouling. You need to make sure there are no bubbles in the epoxy when attaching the transducers as this will affect the signal transfer (the sound waves will travel much slower through air than through a solid surface), an ineffective signal may affect the ability of your device to prevent the attachment of marine foul.

It is also essential to position your ultrasonic system transducers correctly, Ineffective positioning could mean that not all of the hull is covered and therefore reduces the maximum cleaning efficiency. Boat owners should consult our expert team if they aren’t sure about the optimum position for the transducers on the hull or for any other questions related to your ultrasonic antifouling needs.